Verify traces maintain strain when thoroughly assembled, document tension at start and quit. This test is usually conducted for sixty minutes to make sure the method fulfills the acceptance requirements.

Furthermore, FATs assistance to determine that's liable for the issues that are identified. Sometimes the problems are classified as the producer’s responsibility, e.g. an instrument doesn’t function adequately, together with other times These are the customer’s duty (for example, if a buyer decides after observing the Bodily format they want to reconfigure the look, the manufacturer can transfer things all-around ahead of shipping it to website).

Should the testing will not be done, and there are noted concerns when delivered to the job, these could trigger substantial implications associated with:

The protection of one's staff is often a best worry so the standard assurance offers you the relief that all factors of one's procedure are functioning the way they must, and within the full variety of operating requirements.

Okay… transferring on to test the remainder of the PLC digital inputs, When the product which will be linked to the digital input is passive, like an easy change, you can simulate the signal by connecting a piece of wire into the terminal blocks.

This proactive approach not merely accelerates the testing system but will also instils self esteem inside the solution’s dependability and overall performance, demonstrating the company’s motivation to providing a significant-high quality item that satisfies buyer anticipations.

The customer could need a selected verification. The seller usually begins by examining if the unit matches the drawings produced during the manufacturing approach.

The Fats is enough time to find out failures or troubles, establish reliability, validate efficiencies, and check out how the machine should really cope with failures. The test program ought to be organized up front and submitted to the supplier as A part of the Ask for for Quote (RFQ). The equipment is not going to perform as predicted if the criteria aren’t specified; neither will effectiveness be competently assessed. Obviously point out inside the deal all of the tasks, accountabilities, and deliverables, within a measurable way. These needs to be quantifiable and agreed upon to do away with finger-pointing.

Body fat can also be vital from the legal and contractual perspective. It ensures that the devices sent to you aligns with the stipulations outlined in the purchase deal. By fulfilling these obligations, Body fat presents legal safety and fosters trust among companies and consumers.

The customer can qualify the tools against the contractual agreement as per the get specifications.

If the program in dilemma is huge more than enough to influence the process owner’s facilities, laboratory format or utilities or if there are actually any queries pertaining to moving the technique into your owner’s facility, it is highly advisable that anyone accountable for the proprietor’s Bodily plant/facility be invited to go to Fats.

This can be what I want to simply call a Doc Acceptance Test which is definitely a built-up identify as I don’t Believe There click here may be such detail as Document Acceptance Test but The purpose which i wish to make to you being an automation engineer is that Factory Acceptance Test is not a complicated concept and we do these acceptance tests numerous periods a day working on other jobs.

A Factory Acceptance Test (Excess fat) is usually a method where a manufacturer tests a device or process prior to it truly is shipped to the customer. The goal is in order that the machine or program fulfills the necessities that were ordered by The client.

Doing this makes it a lot easier for all functions by getting rid of next-guessing. Specify just how long the machine really should be dry-cycled; 24 hours minimum amount is usually recommended. Specify the amount of packages really should be made and at what velocity. Specify disposal strategies for concluded packages. Though you’ll purchase the FAT, most tools suppliers will comply with a provision that When the equipment fails, any subsequent test is totally free. Owning an in depth test plan may help ensure that you don’t limited-alter the Excess fat. Accomplishing a brief, shallow Extra fat will inevitably exhibit up as read more a dilemma in the third shift, nine months in the future.

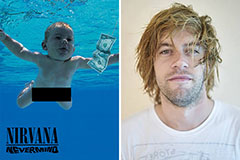

Spencer Elden Then & Now!

Spencer Elden Then & Now! Jenna Jameson Then & Now!

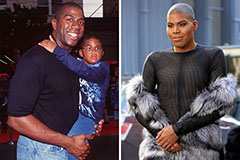

Jenna Jameson Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!